The manufacturing industry is extremely resource-intensive and highly reliant on both pipelines and automation in order to complete tasks in a timely manner. Swami Nandan has over 18 years of professional experience in information technology, and he is an expert driver of the digital transformation vehicle across manufacturing operations. This makes processes more efficient by relying strategically on technology.

Mr. Nandan has delivered initiatives all along the manufacturing value chain by utilizing his expertise in technology program management and information technology (IT) in the heavy manufacturing industries. Statistical analysis, artificial intelligence, simulation, and information security are some of the areas of information technology that he has in-depth knowledge of. He has used this knowledge in conjunction with his fear of niche-finished products, product lifecycle management, quality, and environmental safety.

He has combined his knowledge in these areas to create a road map for the manufacturing industry to follow in order to successfully implement digital transformation operations. The Swami When it comes to driving digital transformation in the industry, Mr. Nandan puts his talented mind to the test. As a forward-thinking manager, he is in charge of directing cross-functional teams in the implementation of smart factory initiatives.

Read More: Cyber Threat Report: Major Breaches for the Travel Industry

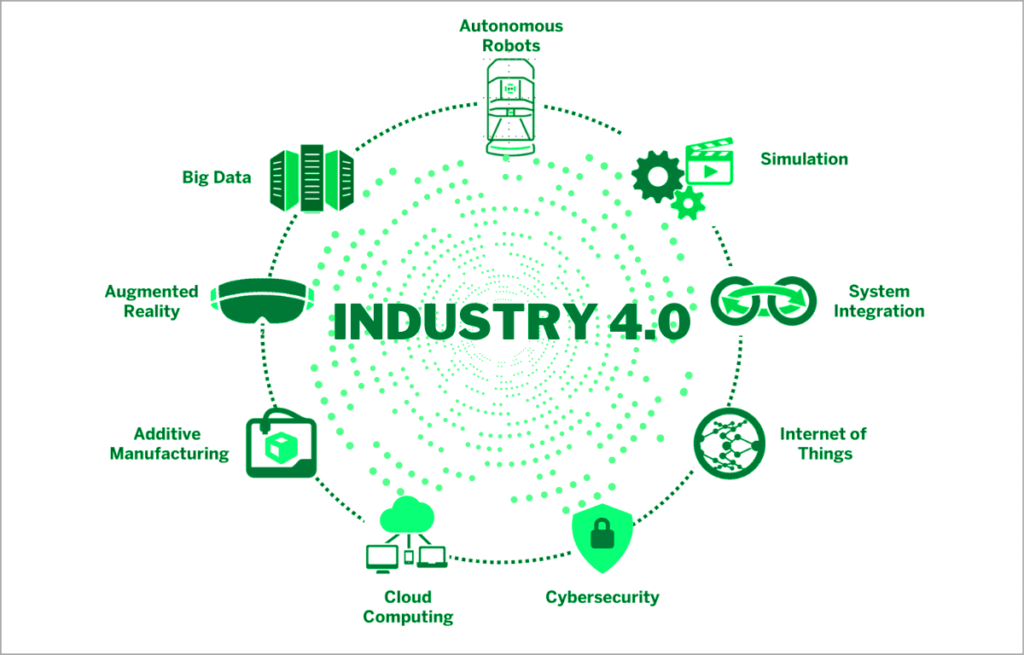

The Role of Industry 4.0: The manufacturing industry is becoming more digital

Some of these initiatives include SCADA, Production Executing Systems (PES), Product Lifecycle Management (PLM), Quality Management Systems (QMS), and Environment Health and Safety Management Systems (EHS). His projects of transformation made use of the principles of Industry 4.0, which are essential for digitally transforming an industry and making it more efficient. Unified Namespace, the Industrial Internet of Things (IIOT), Additive Manufacturing, Blockchain, and the implementation of Ontology and Large Language Model are some of the emerging technologies associated with the advancement of Industry 4.0.

Mr. Nandan began his foray into the digital world by attending the esteemed TMBU University in India. There, he earned a Bachelor of Science and Engineering in Computer Science and Engineering and went on to launch his career in the field.

Later on, he went on to earn a Post Graduate Diploma in Advanced Software Design and Development from the esteemed University of Texas at Austin. Following that, he continued his education by enrolling in the university’s Post Graduate Program in Artificial Intelligence and Machine Learning.

Because of his academic achievements, he was offered a position as the Senior Delivery Manager at Tech Mahindra Ltd., a multinational information technology services company. In this role, he was responsible for managing cross-functional teams consisting of a large number of engineers and technicians to ensure that valuable operational projects were completed on time and within budget.

During this time, he worked as an IT consultant for global oil and gas service companies, where he successfully implemented zero-touch automation and significantly improved operational efficiency. This experience formed part of his IT mindset. Executives who oversaw Field Services Projects costing multiple millions of dollars were also provided with real-time visibility thanks to this automation. He established an Innovation Lab, where he showed the internal digital teams the realm of possibilities that were possible.

This initiative was instrumental in securing funding from businesses for significant projects. In addition to this, Tech Mahindra presented him with the prestigious GURU award in recognition of his significant contributions to important transformation initiatives within the Energy industry. Apprentices are being guided and instructed by him in the hopes that they will one day be able to function as part of a high-performance team.

The manufacturing company he worked for saw an increase of 18% in productivity as a direct result of his consistent adoption of new design practices and technological advancements.

Mr. Nandan was moved to the position of Business Development Director at Blackstraw LLC, a global AI consulting firm, where he worked for almost a year after being transferred there. He designed, constructed, and put into operation end-to-end machine learning (ML) pipelines, and as a result, ML algorithm optimization led to a 20% performance improvement. Swami Mr. Nandan managed a group of data scientists and engineers to create predictive models for demand forecasting, behavior-based buying, customer churn prediction, and preventive and prescriptive maintenance. This accomplishment was made possible thanks to Swami Mr. Nandan’s leadership.

He collaborated with teams that were comprised of members from different departments in order to address these business areas, implement AI solutions for those issues, and then translate those solutions into technical requirements for the company. His journey through digital transformation brought him to LTI Mindtree, where he worked as the Account Director for one year. Swami Mr. Nandan employed a deliberate and systematic construction strategy to assemble teams consisting of engagement managers, technical architects, and service delivery roles.

Swami Mr. Nandan was able to propel the adoption of Industry 4.0 policies in the manufacturing industry thanks to his expertise in digital transformation, which he gained through all of these experiences, which led to his promotion to the position of Senior Manager at Panasonic Energy of North America. When he implemented artificial intelligence for asset maintenance, he adhered strictly to ISA95 standards. As a direct consequence of his work, overall productivity increased by an astounding 30%. He implemented process improvements to Manufacturing Execution Systems in order to improve their level of efficiency and productivity, and as a result, he saw a rate of improvement in SLAs of twenty-five percent.

Mr. Nandan is a highly regarded digital transformation specialist expert who possesses synergized strengths in operations management, emerging technologies such as artificial intelligence, and global quality standards. Because of his profound expertise in artificial intelligence, the quality of manufactured products, asset maintenance, and delivery commitments have all been improved. He accomplished this by using statistical and financial modeling. His expertise in digital transformation includes obtaining global certifications like ISO 27001, ISO 9001, and ISO 14001. In order to broaden the applicability of self-supervised learning in machine learning models, he makes use of cutting-edge methods such as computer vision, federated models, and natural language processing (NLP).

He works hard, with the assistance of his team, to produce high-quality manufactured goods that are in accordance with the ISA95 guidelines and the automation pyramid. His grounding in platforms such as the hub and spoke model, the Unified Namespace, and PLM contributes to his exceptional performance in the Industry 4.0 space. Mr. Nandan has constructed multi-million dollar ROI projects as a result of the rigorous process he employs for the purpose of ensuring quality. This includes utilizing his Digital Transformation Maturing Assessment frameworks to gain insight into the state of the legacy infrastructure of his customers, ideating solutions, collaborating with his team of fifteen members to implement Industry 4.0 policies, and testing for quality assurance and security.

Read More: How NFTs Are Disrupting the Music Industry: An Inside Look